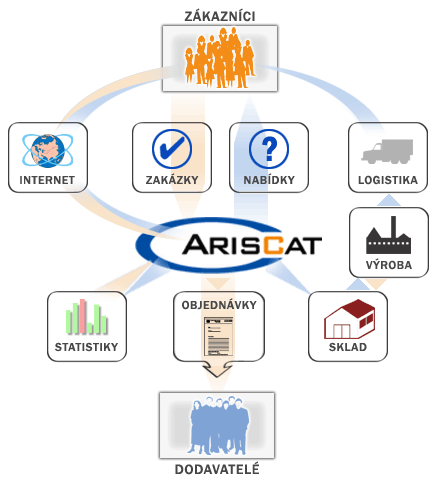

ArisCAT is a complete information system for business and manufacturing companies. It includes expanded CRM, simple and quick bidding, order management, and customized production and warehouse management. It allows to keep an unlimited number of warehouses and to organize the material and goods into storage groups. Manage outputs and statistics can be customized and exported to Microsoft Office documents. The user of the program can change the print assemblies and masks for configuring the products themselves. Customers can take advantage of the integrated online store and mobile app that the manufacturer can customize.

The Customer module is used to record customers contacts. Provides information about contact persons, company headquarters, turnover, and customer payment morale.

For example, it is possible to set the default currency for orders, discounts or premiums for individual products and other settings.

They allow you to generate quotations very efficiently, tilting them into orders and then into production. In addition, the module provides information on the payments made and the documents created for the individual orders.

This module allows to plan production based on orders or past production and to plan the consumption of raw materials based on consumer standards (production recipe) and the current state of the warehouse. Manages production preparation, evaluates production, prepares daily production, tracks long-term production and consumption patterns of raw materials, planned and produced quantities.

The installer module provides an overview of all fitters working for the business, their price parameters, turnaround and other statistical information.

The Documents module contains a list of all issued documents:

In the Stock module, you can divide all products into one or more warehouses, warehouse groups, and subgroups. In individual warehouses, you define stock cards, purchase definitions (warehouse number and principal supplier's description), purchase, consumer and sales prices, and other settings. You can set up conversion units (e.g., 1 roll = 30 m) and definition of fast material transfers.

Used to set all system parameters, from product definition, print reports, user actions, and central parameter settings.